How to calculate the ROI of logistics efficiency

Measuring efficiency is always a challenge, but without concrete numbers every decision remains an assumption. In logistics, where every lost minute or poorly used cubic meter translates into costs, calculating the ROI of logistics efficiency becomes essential. It is through this calculation that an SME can prove whether the investment in improvements — whether in processes, technology, or training — is truly generating a return.

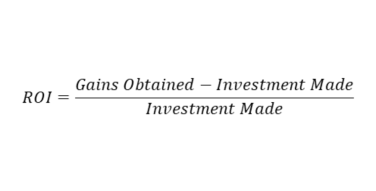

The starting point is simple: ROI means “Return on Investment,” or in other words, the gain in relation to the amount spent. In logistics, this gain can appear in many forms: fewer wasted work hours, reduced picking errors, fewer returns, lower transportation costs, better warehouse space utilization, or even higher customer satisfaction, which leads to loyalty. All of this can be translated into monetary value, even if not always immediately.

To calculate the ROI of logistics efficiency, data needs to be collected before and after improvements. How long does it currently take to prepare an order? How many errors occur per thousand shipped lines? What percentage of returns are due to internal failures? By comparing these indicators with the results after implementing changes, operational differences can be transformed into euros. The formula follows the classic approach:

Take the example of an SME that decides to implement simple organization and digitalization improvements in its warehouse. The investment amounted to 20,000 euros. If, in the following year, the reduction in operational costs and losses added up to 60,000 euros, the ROI would be 200%. In other words, for every euro invested, the company obtained two in net return. This example shows that the ROI of logistics efficiency is not an abstract metric but a concrete figure that supports strategic decisions.

Another key point is that ROI should not be seen only in the short term. Many logistics improvements have cumulative effects: better route organization may reduce costs today, but it can also open room for new customers tomorrow. Likewise, investing in training or digitalization may seem expensive at first but generates sustainable results over several years.

Most importantly, calculating the ROI of logistics efficiency provides a strong argument within the company. It allows operations managers to justify to financial directors that the proposed improvements are not costs but rather levers for profitability. At the same time, it fosters a results-oriented culture where every project must prove its impact.

In the end, measuring return is as important as implementing improvements. Logistics efficiency only becomes real when it stops being perception and turns into numbers. For SMEs, this is the path to transforming logistics from a cost center into a true engine of competitiveness.

Want to transform your operation and measure the real impact of efficiency? Talk to us.