SpaceInvader in Portugal – Official partnership with KronoLog Solutions

KronoLog Solutions is the official SpaceInvader partner in Portugal. Together, we help companies increase load utilization per truck, reduce transport costs and emissions, without changing their fleet or handling equipment.

SpaceInvader is a modular, stackable pallet rack system that allows better vertical use of space inside the truck and in the warehouse.

In practice, this means moving more product per trip, with higher load stability, without investing in new trucks, trailers or special forklifts.

The system is robust, certified, simple to operate and designed for real-life transport, distribution and retail operations.

Many companies face the same situation:

- Trucks driving long distances with unused “air” inside

- Increasing pressure on transport costs and driver shortages

- Stricter sustainability and emissions targets

In short, companies pay for trips that could carry more load, increasing cost per unit and carbon footprint.

SpaceInvader was designed to tackle this structural problem: increasing useful load per trip, without changing the fleet or completely redesigning the operation.

In simple terms:

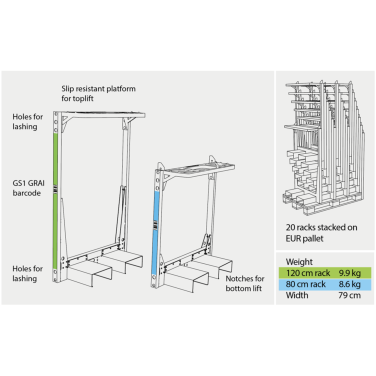

- Each SpaceInvader unit is a metal rack that fits into each pallet end;

- It allows pallets to be safely stacked (pallet + double rack + pallet), creating a second load level;

- The system is compatible with standard pallets (e.g. EUR/EPAL) and most trailers;

- Handling is done with standard forklifts – no special equipment required;

- When not in use, the system can be stored in a compact way, in batches of 20 racks.

The result: more load in the same truck, with stability and safety, while protecting product integrity.

Typical benefits for companies that implement SpaceInvader include:

- Lower transport cost per unit

More load per trip = fewer trips for the same volume. - Reduced emissions and better sustainability performance

Fewer kilometres, fewer trucks on the road, lower carbon footprint. - Mitigation of driver shortage pressure

If each driver can move more load per route, the need for additional vehicles for the same volume is reduced. - Better use of warehouse and cross-dock space

In many cases, staging and consolidation areas can be optimized, avoiding pallet congestion. - Improved load stability and safety

The system is designed to increase load stability and reduce the risk of product damage. - Flexible, phased implementation

Start with specific routes (e.g. high-density lanes) and scale as results are confirmed.

SpaceInvader brings the technology.

KronoLog Solutions ensures operational design, local implementation and on-the-ground support.

The work is typically structured in three stages:

- Diagnosis and sizing

- Analysis of current flows (volumes, routes, product types);

- Identification of high-potential lanes;

- Target scenario and benefits estimation.

- Controlled pilot

- Pilot implementation on selected routes;

- Training of warehouse, transport and logistics teams;

- Measurement of results vs. the current baseline.

- Scale-up and integration

- Adjustment of the model (rack volumes, routes, processes);

- Integration into SOPs and operational checklists;

- Initial support until the new way of working is stable.

The goal is not just to “rent racks”.

The goal is to improve logistics efficiency and reduce total transport cost in a sustainable way.

SpaceInvader is particularly relevant for companies that:

- Have regular flows between DCs, platforms and regional hubs;

- Work with palletised products that can be safely handled with controlled stacking;

- Operate medium and long-haul routes (national and international);

- Feel pressure on transport costs, fleet capacity and CO₂ targets.

Typical sectors:

- Food and non-food retail

- FMCG

- Industrial B2B flows

- Logistics service providers (3PL/4PL)

The best way to see if SpaceInvader is the right fit is to test it.

Typical process:

- 30–60 minute scoping call

- Quick analysis of 2–3 high-potential routes

- Pilot proposal with a defined number of racks and duration

- Joint assessment of results and decision on scale-up

1. Do we need new trucks or trailers?

No. SpaceInvader is designed to work with standard fleets, subject to some basic technical requirements, which are checked in the initial diagnosis.

2. Are our current forklifts enough?

In most cases, yes. The system is designed to be handled with standard forklifts.

3. Is the system safe and certified?

Yes. SpaceInvader operates under strict safety requirements. The Portuguese implementation design includes risk assessment, training and clear procedures.

4. What level of investment are we talking about?

Initially no, as we work in a pooling system. It depends on the number of routes, load volumes and ambition level. That’s why the first step is a quick assessment to estimate potential gains and size the investment rationally.

5. How do we start?

Simply schedule a conversation with KronoLog Solutions. From there, a pre-study of your key routes is done and a tailored pilot is proposed.